Industry 4.0

AI and Internet of Things are reshaping the manufacturing industry. Talk to any industry expert and mention “Industry 4.0″, you are about raise a few eyebrows. Like everybody, they are confused and will claim they are doing it too. Like AI, is it a Buzzword ? a futuristic catchphrase ? . Call it what you want, and trust me when I tell you this – ” The force is strong with this one “.

Fine, What is Industry 4.0 ?

Forbes defines industry 4.0 as “Industry 4.0 builds on the previous three phases of industrialization – mechanization, mass production and controls. It’s an intelligent production environment enabled by an integrated platform of enterprise data systems, the Internet of things (IoT) and cloud computing.”

Source – Accenture

Cool, What will Industry 4.0 do for us ?

Industry 4.0 would give us valuable insights into variables that cause performance dips, machinery malfunctions, bottlenecks and basically change the current landscape of maker to consumer relationship model. How you ask ?

Forbes reports that consumers are getting may more concerned about purchasing goods from companies that have strong CSR policies. Companies with carbon positive emission standards, stronger employee welfare standards are becoming more and more effective with consumers.

4.0 is more than just efficiency. It give manufacturers the power to customize products easily, hence finding a more loyal customer base, leading to bigger satisfaction rate and higher retention.

Sounds good. Who is doing this ? – The curious case of Tesla.

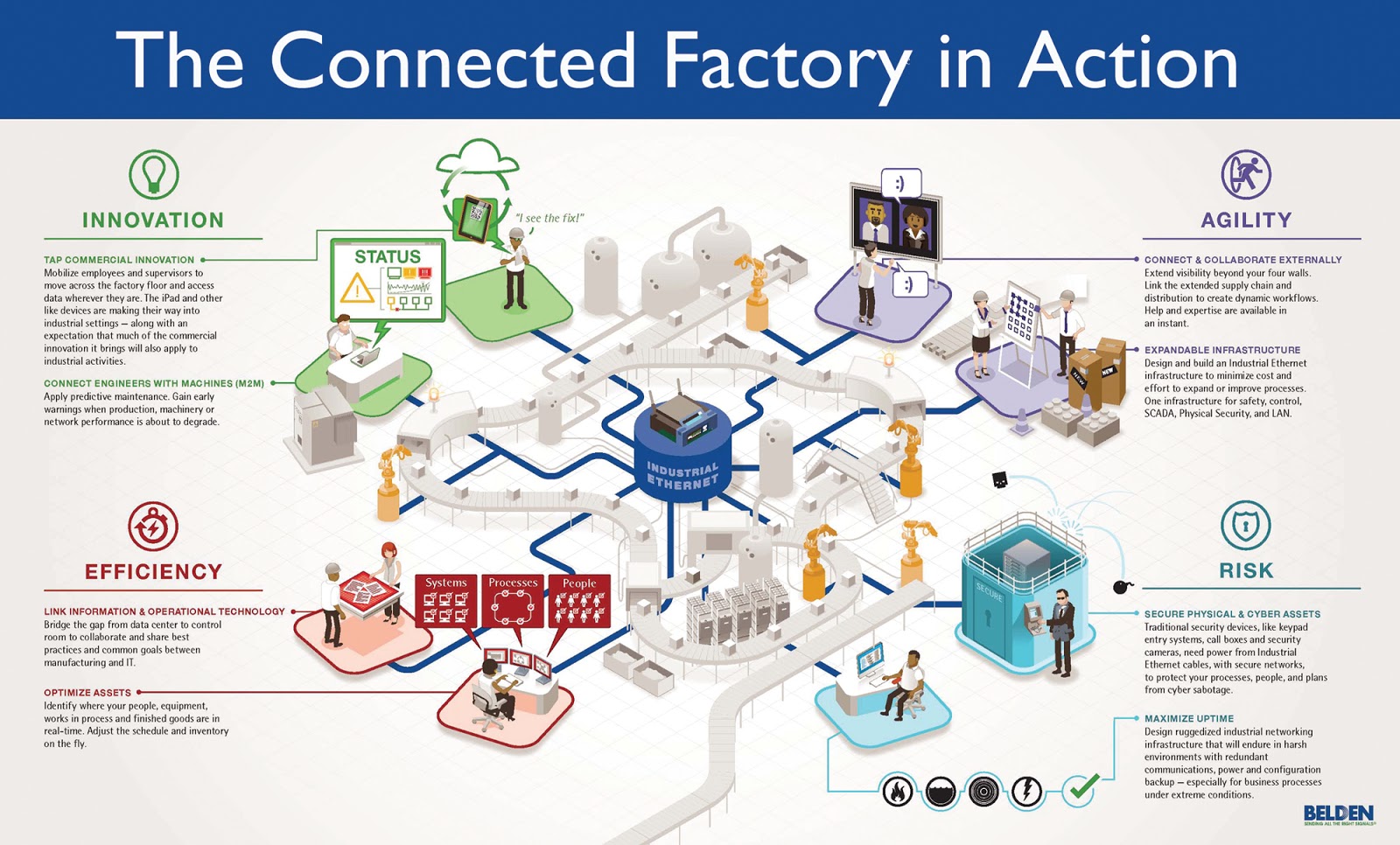

Although there are a large number of auto manufactures, there is hardly any that garner as much attention as Tesla. Elon has revamped the way USA looks at manufacturing. The ultra modern connected factories are the best examples of connected factories through IoT. Tesla pretty much does every aspect of what was previously mentioned in the above paragraph, by following the exact process as below :

Source – KPMG, electronics weekly

A Strategic Perspective:

As old school manufacturing processes are changing, so are business models. This poses an important questions for executives – Can you recognize and device a plan to counter new technologies ?

Let us think about a Platform where an open source software solution can be implemented in the manufacturing context. Platform that have algorithms built in and you purchase the IoT – Cyber physical machines and you are ready for production with the maximum efficiency from day one.

SLM solutions – 3D printer manufacturer and ATOS, IT services company are working a project to develop this platform market place to unify manufacturers.

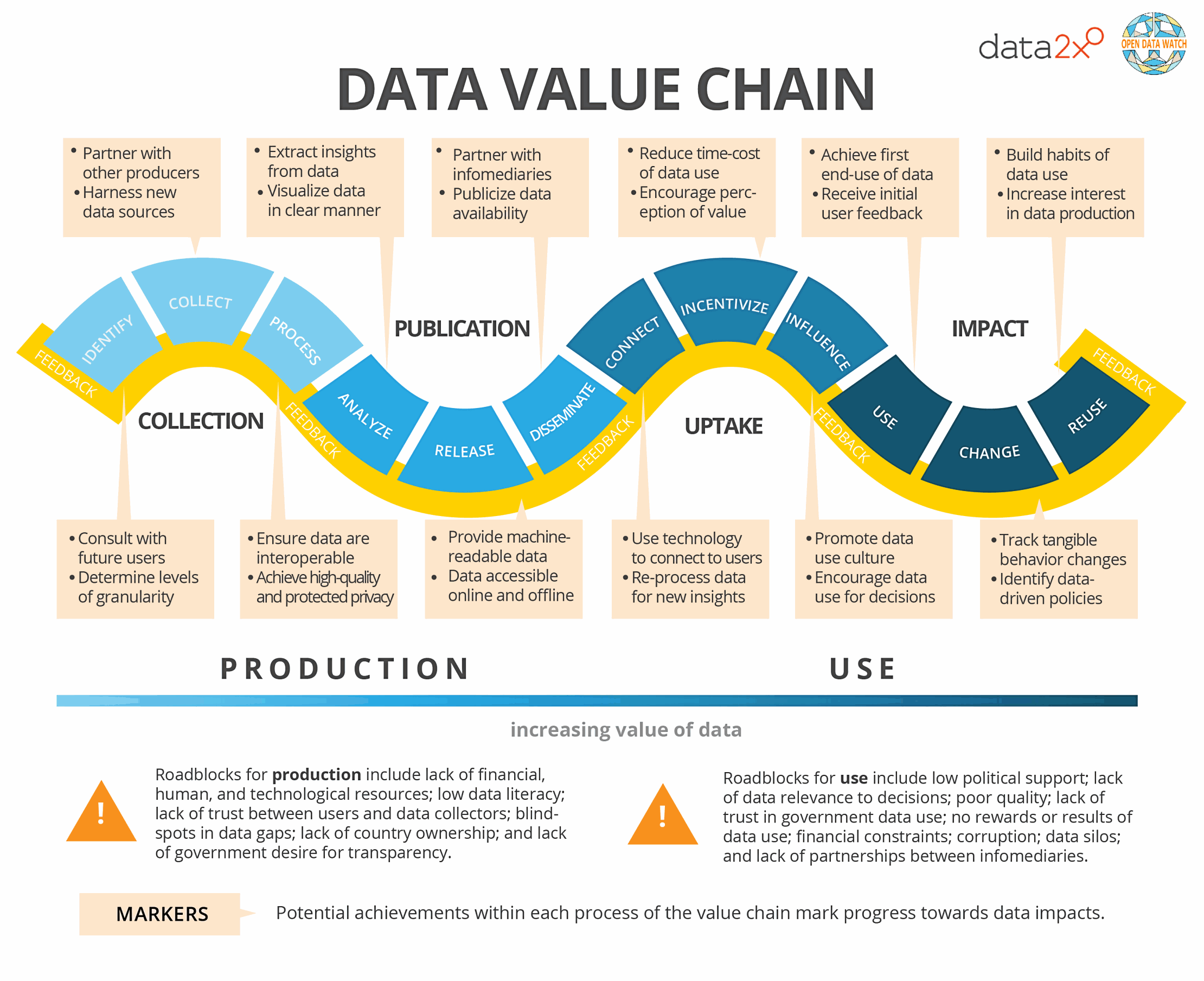

The new value chain of industry 4.0 could look something like this ;

Source – OpenDataWatch

Long Story Short

We wouldn’t have seen an Industry 4.0 or smart factories with the evolution of Internet of Things. Self governing devices are the new base for development in manufacturing. The time for change is now. To get the most out of this, companies must think past their business model and think about Digital Transformation. Yes, manufacturing companies will be in the market for the hottest talent in AI, Big data and Analytics in the next 4 years.

Sources :

- https://www.mckinsey.com/business-functions/operations/our-insights/manufacturings-next-act

- http://www.iotevolutionworld.com/m2m/articles/401292-how-industry-40-the-internet-things-connected.htm

- https://opendatawatch.com/publications/the-data-value-chain-moving-from-production-to-impact/

- https://cdn.iveybusinessjournal.com/wp-content/uploads/2012/01/Hollingworth-Conversation1.jpg

- https://www.electronicsweekly.com/news/business/industry-4-0-not-reaching-factory-floor-2017-06/

- http://www.duppeditten.com/blog/connecting-the-dots

- https://www.forbes.com/sites/willemsundbladeurope/2018/07/30/whats-at-stake-in-the-race-to-industry-4-0/#52727bc17d11

One comment on “Industry 4.0”

Comments are closed.

Great Article. I believe that Industry 4.0 indeed is a Buzzword. In my opinion it is hard to draw a line between an “Industry 4.0” Process and a “non Industry 4.0” Process. There is clear distiction. The value of the term Industry 4.0 lies in it being a Buzzword. Now that everyone is talking about Industry 4.0, companies around the world want to keep up with that movement and invest into their processes to integrate more state of the art technology. Similar to the concept Apple and other companies use to market their products. Siri, Nightshift, AirDrop. It has become a thing to give normal funktions a name to make them spread faster. If something has a name, people can start talking about it and spread the idea.