IoTA: Internet of Things [for] Aerospace

Nick Colsey (VP of Business Development @ Sony Electronics), JB Straubel (co-founder of Tesla), and John Donovan (Group President @ AT&T) discussed how the Internet of Things (IoT) applies to each of their fields. When most people think of the acronym “IoT”, they tend to think of concepts related to the topics discussed by the three speakers on Friday. However, the idea of IoT extends far beyond consumer electronics and entertainment. As an engineer at Boeing, I was curious to know how this idea was being applied (if at all) to the aerospace industry and was pleasantly surprised by what I found.

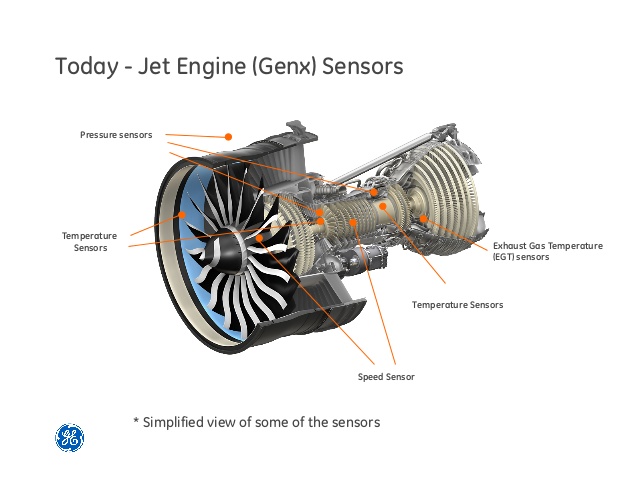

After the mysterious disappearance of Malaysia Airlines 370 in the spring of 2014, there were renewed calls to install black boxes (they’re actually bright orange) which would stream data continuously from airplanes directly to the ground (or the cloud). Although this has yet to happen (the common argument is that the cost of streaming all the data recorded by the black boxes would be astronomically high and the benefit would be marginal as air crashes where the black boxes aren’t found are almost nonexistent), aircraft manufacturers and suppliers are using the IoT concept to gather other data to drive design improvements and decision making. Bhoopathi Rapolu discussed a new innovation from Bombardier in his Aviation Week article titled “Internet of Aircraft Things: An Industry Set to be Transformed.” The engines on Bombardier’s latest aircraft, the C Series, are equipped with 5,000 sensors which generate a staggering 10GB of data per second (the figure below shows what some of these sensors are and where they’re located on a similar engine currently in development by GE to power the Boeing 777X). This translates to, for a flight from Los Angeles, California to Bogota, Colombia (a flight well within the range of the C Series), over half a million GB of data. And this is only for the engines.

“In comparison, at the end of 2014, it was estimated that Facebook accumulated around 600 TB of data per day; but with an orderbook of more than 7,000 GTF [Geared Turbofan] engines, Pratt could potentially download zeta bytes of data once all their engines are in the field. It seems therefore, that the data generated by the aerospace industry alone could soon surpass the magnitude of the consumer Internet,” Rapolu writes. These are scales of magnitude could not have been accomplished without the advancements in computing and data storage that we have today, which leads one to wonder about the possibilities in another decade. The data that’s currently being collected by Bombardier is already being used to improve designs and, ultimately, increase efficiency. The GTF engines installed on the C Series use the data collected to develop artificial intelligence models that can foresee the demands of the engine and consequently adjust the thrust levels. These advances, combined with other technologies, have reduced the fuel consumption of these engines by 10-15%.

The aerospace applications aren’t solely limited to propulsion either. UTAS (UTC Aerospace Systems) unveiled at the 2017 Paris Air Show its Ground Maneuvering Camera System. According to UTAS, “The GMCS enhances situational awareness by providing pilots video and camera views of the nose gear, main gear and wingtip areas to aid in taxiway maneuvering. The system also offers a unique passenger experience by providing a wingtip to wingtip view from the aircraft’s vertical stabilizer through in-flight entertainment (IFE) video. The system includes high definition digital video cameras as well as a taxi camera interface unit. Designed to reduce the risk of parts obsolescence, the system can be configured for specific customer requirements.” Additionally, UTAS has been selling its Health and Usage Monitoring System (HUMS), which collects data from across the airplane and uses it to help airlines make more informed decisions on maintenance and fleet management. Their Vice President of Aftermarket Services, Ajay Agrawal, said at the 2017 Paris Air Show that based on the data they collect, they’re able to provide specific recommendations on which components to replace before they fail.

Despite generally being several years behind other major industries in adopting new technology, IoT is an area where the aerospace industry has kept pace with its peers. The always-increasing complexity of aircraft (and spacecraft) means that there is still significant potential to collect, connect, analyze, and apply this data to improve the safety and efficiency of modern air transport.

One comment on “IoTA: Internet of Things [for] Aerospace”

Comments are closed.

This is a very informative article. Its high time the aerospace industry adopted internet of things. Your referral to Malaysian Airline flight 370 is very significant. We will never really know what happened on that flight. However what if we had active streaming of data during the flight? Most of our questions would be answered such as the last position the flight last transmitted, the magnitude of impact, the nature of the crash e.t.c. This would speed up rescue missions. With this data, we could even unravel the mystery behind the Bermuda triangle. Its not just important in crashes but also in monitoring the state of the aircraft so as to predict and potential dangers early enough in flight such as engine failures, bird strikes and flight take over scenarios such as the 911 attack. Internet of aircraft would improve flight safety and aircraft maintenance. However, have you thought about the potential risks and dangers?