Art vs Automation – the Rolls Royce dilemma

Art vs Automation – the Rolls Royce dilemma

By Victor Moran

At the beginning of the 20th century, the Rolls Royce company was founded by “Henry Royce, a successful engineer and Charles Rolls, owner of one of the UK’s first motor car dealerships” (1). By 1907, the Silver Ghost was declared the best car in the world after covering 14,371 consecutive miles, longest ever. By 1990, the company’s production rights were bought by the German giant BMW marking a big milestone for the company.

The long manufacturing tradition goes back to the perfection of every single aspect of the car, overall 65% of the Rolls Royce cars ever made are still on the streets. Part of this tradition resides around their low tech high manual operation. There are multiple examples of this through their process.

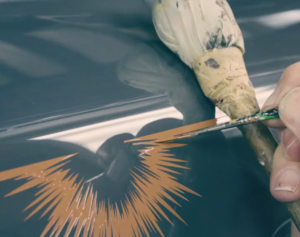

For example, there is only one person allowed to perform the paint of every car at coach line, his name is Mark Court. This is part of the craftsmanship and artistry involved in making a Rolls Royce, There are no robots, machines and or automation allowed to perform this job at their manufacturing site. There is no room for mistakes as there is no way to undo the lines once done.

Another good example is the woodwork which is one of main trademarks of every produced car. The attention to detail and the “Wood is one of the defining features of a Rolls-Royce,” per Jonathan Peedell, who is the Production Manager at their woodshop, “The craftsmanship seen in a Rolls-Royce goes beyond traditional automotive woodwork,” he says. “It is closer to what you would find in fine furniture or in a super yacht. (3)

Even on these days of high digitalization and automation, the engines of all Rolls Royce automobiles is still hand build, making every unit produced a unique piece of art (4).

So with these high levels of artistry behind every single car and the push for more efficient and robust manufacturing process during the digitalization age, where and how do you find the right balance? Where does the tradition face the financials and the tradeoffs starts being discussed?

Arguably, the current model works given the advantage the manufacturer has to just charge the end customer all the associated costs for these inefficient but highly valued additional services like the wood and paint jobs. You could argue that it can be compared to buying art and the fact that buyers can just pay whatever you ask them for especially in a positive economic environment. The question is what happens once the market shrinks and these luxury items get affected? At that point do you after productivity while potentially compromising the value added of your product? Or do you wait patiently while the market bounce back? The issue is you can’t lay off your artists right? They are the secret sauce of the company, you can’t shut down your locations? So how do you reduce your cost structure while sales are down?

For a company that has been on business these questions are for sure once that they ask themselves periodically, at the end, it is a business and they are measured on financial performance. They product has never been questioned however the model can and should be questioned periodically. Technology should be incorporated across the board as long as it doesn’t affect / hinder the company’s essence. With more competition on the luxury car market, it won’t get easier for Rolls Royce.

Reference:

- https://www.rolls-roycemotorcars.com/en-GB/house-of-rolls-royce/the-history-of-rolls-royce.html#

- https://www.linkedin.com/company/rolls-royce-motor-cars/

- https://www.rolls-roycemotorcars.com/en-US/bespoke/the-art-of-wood.html

- https://www.catawiki.com/stories/4215-the-history-of-rolls-royce-in-10-interesting-facts

10 comments on “Art vs Automation – the Rolls Royce dilemma”

Comments are closed.

A good article and it shows the interest people still have in the personal touch.

Great article, I agree with you on this, I think there will always be a market for hand made products and craftsmanship that simply automation will never be able to achieve. As humans we will always appreciate the nuances in the work of the artists that make our products. Machines will never be able to make this connection therefore automation will never be able to replace an artists. Of course people will love to emulate the actual lines in the rolls royce with machine made lines but the people who can afford it will always prefer to have it done by hand.

Interesting article! I agree that there will always be an appreciation for craftsmanship when it elevates the product to be perceived more as a piece of art. Though Tesla can also attest to the fascination and awe their robotic factory floor produces tour after tour. It seems there is human appreciation for both ends of the spectrum – something produced totally by hand or entirely by machines. In times of economic downturn, I guess Rolls Royce could potentially bolster themselves by expanding into a mid-level market – keeping their luxury item production process intact and exploring cost-cutting avenues on a mid-level model (a hybrid human/machine production process of sorts cutting corners and producing a car that’s price tag has more mass appeal). But then again, that might muddy the brand. Given the enduring status symbol and legitimacy that Rolls has cultivated, I would proffer that they can weather the storms – though in future, may transition to even more of a collectors item than they already are…

Rolls Royce can easily implement more automation in their process of manufacturing. I think if they do so they will lose what makes them different: the handmade component involved in the production of their cars.

According to Bause, Rolls Royce workers should not only pay attention to the cars but should also love the details. An average car takes about 25 to 30 hours to build, but it takes between 400 and 450 hours to assemble a Rolls, as long as the customer does not make extravagant orders. A common car is assembled 90% by robots. On the other hand, to assemble a Rolls Royce, the percentage reverts: humans do 90% of the work. Each luxury car goes through about 30 workers to be completed.

Every car that Rolls Royce produces is an artwork which can be compared to purchasing a painting—Rolls cars have a crafted design that has become legendary. I think people buy these cars because of their uniqueness and the many options to customize them.

Interesting arguments.

If we all were completely rational beings, we would all have valued man-made diamonds as much as natural ones, if not more, given the quality can be near perfect for the manufactured ones.

Don’t get me wrong. I’ve been making a living off of automation from auto industry to info tech/data science, but I still prefer natural diamonds 😉

I completely agree with your point. Rolls Royce can charge huge premiums because their value proposition is the luxury handmade car. Tough, I find it a risky strategy. Human dependency can lead to severe problems for the company. They can now offer little variability on their products because each car is made by the exact same highly specialized team. What happens, however, if the paint specialist, Mark Court, get sick or has an accident? Is the whole production line stopped? Or the paint will be made by someone else who is not as skilled? They must make sure they can transfer specialist’s knowhow to future generations. In the other hand, automation not only cuts costs, but it also offers a reduction in variability because is human independent.

I really enjoyed your article! I wasn’t aware that their cars were handmade, and I think that’s very interesting in this day and age. I definitely think that if the markets continue to increase their business will continue to boom because of how they aren’t mass produced. Almost every product you buy today was mass produced, and while many are fine with that, some aren’t. Some want the personal aspect of buying handmade products, and I think that if the markets were to increase then they will be successful. I also agree that if there was an economic decline, then their business could go under since they have artists, not robots. Thanks for the great article!

I think this is a great post!

I found it interesting that you mentioned that there are no robots or automation allowed to perform the paint job and at the same time mentioned there was not room for mistakes. Personally, I had always thought that machines or robots would have higher levels of accuracy than humans did when performing repetitive tasks because humans would be more prone to accidents or slip ups. The instances where humans would perform better would be during rare or unexpected situations that machines were not pre-programmed for.

I also do believe that part of what makes those cars (an other ‘handmade’ or ‘artisan’ goods) so expensive is that fact that they are made by hand and each individual one is in a sense, unique. No one would really want to be paying large amounts of money for something that’s mass produced by robots. This may lead to some interesting developments in how art is made in the future!

Great post! I did not know that Rolls Royce were made with such detail. I agree with you on the importance of the artistry that comes with the brand, which is probably a differentiator as well. I have the feeling that since it is what separates them from their competition and allows then to charge a premium they have no real motivation to embrace automation.

Great read. I think that no matter how much technology advances, the human touch that defines art and artistic expression in products is difficult to replace because people value that human centered touch and a uniqueness to what they use.