The Zara Phenomenon: due to Cloud Computing

The retail industry is widely adopting cloud computing, with its investment in cloud technologies skyrocketing from $4 billion in 2011 to an estimated $15 billion in 2016. (http://www.cio.com/article/3156599/cloud-computing/3-ways-cloud-computing-is-revolutionizing-the-retail-industry.html) Like the banking and manufacturing industries, retailers are recognizing the transformative role of Cloud Computing in today’s digital world.

The way the retail industry is embracing cloud computing is working out what the popular products will be by predicting trends, forecasting where the demand will be for those products, optimizing pricing for a competitive edge, manage effectively their inventory and increase supply-chain performance.

Zara is one of the most known retail companies in the world. What some people don’t know is that the pillar of their success is actually their technology infrastructure, which is based in cloud-computing and Big Data.

The so-called fast fashion model that Inditex has pioneered, has been vital to its phenomenal growth from a small manufacturer based in the small town of Arteixo, in Gallicia, northern Spain to the world’s largest fashion retailer. The group now includes eight brands such as Pull & Bear, Bershka and Massimo Dutti and has more than 6,500 stores in 88 countries. (https://www.retail-week.com/sectors/fashion/inside-inditex-how-zara-became-a-global-fashion-phenomenon/5065325.article)

The business’ premise remains the same as it is today: to sell well-made, relatively cheap clothes made to the latest fashions, designed and produced by Inditex.

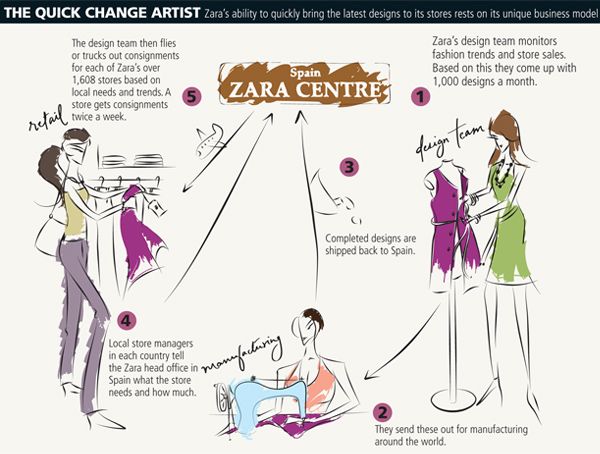

In a world obsessed with speed, the importance of reducing product launch times is one of the competitive advantages companies value most. One of Zara’s strong points is, precisely, cutting its collections’ time to market. That is, it takes them less time to design, produce at their factories, and get their collections to stores than any of their competitors. (http://www.masvoz.net/blog/blogcloud-computing-one-of-zaras-most-successful-tools/). It sounds simple but to react to consumer demand and get designs from the page onto hangers in store in just three weeks requires an agile infrastructure.

New designs are produced in small batches and can arrive in store within three weeks. The small production run, combined with its incredibly quick production and delivery times, enables it to back its winners and disregard unpopular items. (https://www.retail-week.com/sectors/fashion/inside-inditex-how-zara-became-a-global-fashion-phenomenon/5065325.article)

The customer service policy in Zara is focused in this process. Employees and managers talk constantly with their customers to survey what are their fashion tastes in general. Also, they follow first-hand trends daily. But all of this is useful thanks to cloud-computing because that information travels almost in real time from stores to market specialists and designers.

With the information acquired, designers redo the collections, with Zara able to restock its clothing collections in just three weeks, stores end up selling what people are really looking for at all times. Zara does not have one collection per season but five “waves” of articles with new products entering its stores each week.

In addition, they put RFID (radio frequency identification) chips into its clothing inventory to constantly replenish trends at a breakneck pace. The RFID tags ensure that Zara’s inventory will never run dry (or at least not too often). They allow the company to easily track what’s selling well and what’s lagging on the sales floor. (https://www.tradegecko.com/blog/zara-supply-chain-its-secret-to-retail-success)

Finally for all of this to work, let us not forget the importance of logistics. The supply chain of Zara is comparable in speed and efficiency to great delivering companies such as FedEx or UPS. Each Zara outlet sends in two orders per week on specific days and timing. Trucks leave at specific times and shipments arrive in stores at specific times. Garments are already labeled and priced upon destination.

As a result of this clearly defined rhythm, every staff involved (from design to procurement, production, distribution, and retail) knows the timeline and how their activities pan out with respect to other functions. (https://www.tradegecko.com/blog/zara-supply-chain-its-secret-to-retail-success)

This brand’s success story shows the strength of its operations. Its operations strategy, coupled with its efficient supply chain, enables mass production of clothing that they know will sell based on their customers’ needs which leads to well-managed inventories and as a consequence, higher profitability.

Zara is all about staying on top of the hottest trends but its supply chain is the real star of the show, all of the system would not work if it wasn´t for their technology infrastructure which is based on rapid a response system rooted in cloud-computing and Big Data.

5 comments on “The Zara Phenomenon: due to Cloud Computing”

Comments are closed.

Thank you for your post. It is interesting how non-tech industries use technologies to improve their operations. Some years back I used to work in the Danish based fashion retail company and I know how important to keep up the speed of the delivery of the latest fashion trends to the shop floor. Back then we had to do quite a lot of manual work in collecting data from the shops across the world and analyzing the data. Zara was always a benchmark for their ability to react fast to the customer needs. I recommend a great report by PWC – “ Industry 4.0: How digitization makes the supply chain more efficient, agile, and customer-focused” https://www.strategyand.pwc.com/reports/industry4.0

Thank you for your comment Natasha. The article you posted is very interesting, especially where it says that 3D printing is transforming the spare parts value chain and how this will revolutionize the way inventory is handled.

Irene, this was so cool! I love Zara, and never imagined they used such high-tech management techniques.

Natasha, your article was also a very interesting read. The infographics and comparisons communicated the ideas very well.

I think the main factor that makes this technology successful is the “ever changing” nature of fashion trends and the “real time” need for sustaining the products. It is very crucial to the customers experience to be able to purchase their favorite styles in the right season. I think everyone has experienced how disappointing it can be when you finding out an item you really wanted is sold out or not available in your size.

My only worries would be if someone has there own taste in clothes as opposed to fashion trends. Then would big data be able to cover the outliers? I personally am one of those people, and for example I have to look hard to find pretty clothes that are modest at the same time.

Oh, I forgot to add this: Sara Dabzadeh | MS&E 238A.

Thank you for your comment Sara. I agree with you. I think there is a way of making clothes for everyone using Big Data, although I have not seen this yet I think this could be the next big step in the fashion industry.

Users who have LIKED this comment: