Sensor Data and Mars-Drilling

Introduction

Drilling is anticipated be an important activity in the future exploration of Mars. Its primary motivation will be to allow the exploration of the subsurface of Mars, in particular to search for, and eventually study, life on Mars. The scientific value by acquiring in situ samples for analysis is one of the primarily objective for planetary exploration missions. Operating a drill under these harsh environments is an extremely complex task compared to drilling at Earth [1]

Fully Autonomous from Machine Learning Algorithms

A fully autonomous system must allow contingent operations because of large uncertainties, where the control system must complete its task without real-time oversight by humans, and set it self up, initiate the drilling process, stabilize the borehole, remove cuttings, analyze cuttings, directionality maintained, and dispose cuttings.There is no tolerance for the drill to get stuck or mechanical failures in the system, in addition, the system must be capable of self-maintenance.

There is no data available of what is to be drilled, it must anticipate failure situations and recover. All this while managing a tight power and energy constraint and other consumables [1]. The integrated control system is controlled through an onboard computer, sending executive commands to the remote operation and automation subsystem controlling its operations. The computer is responsible for control of all drill mechanics, hierarchical set of high level commands and parameters, and may be set manually remotely to interface with operation.

[2]

Automation

A teleoperation from Earth is not an option with large time delays, requiring a fully automated “hands off” drilling system. There is a huge challenge of drilling in the harsh surface environment on Mars, low temperature and low pressure, close to the triple point of water have its affects on the mechanical and electric systems [3].

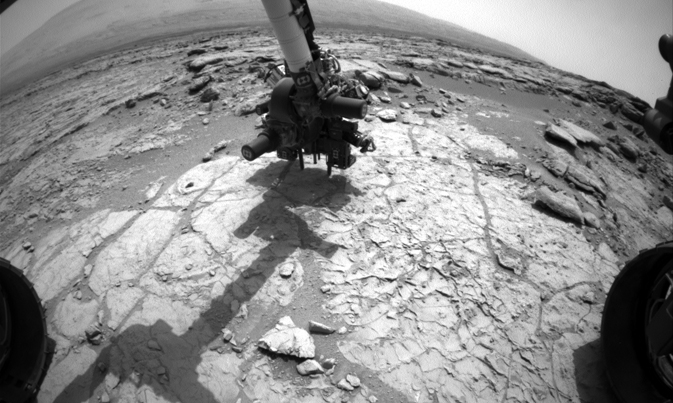

The drill system requires a dynamic and adaptive drill controller, detecting abnormalities during drilling operations, and be responsive to sudden change of condition in borehole by change of speed and forces. The drill must be designed to be rough, and fully automated to handle both consolidated and unconsolidated formations such as; ice, ice-cemented soil, sand, basalt and sedimentary rocks without previous seismic survey of the landing site, detect and recover from down hole faults during drilling operations of high risks, and easy to jam or freeze in the borehole, without human interaction.

Autonomous Robotic Drilling requires a high degree of autonomy, one not yet achieved in totality even for drilling on Earth. The software must include low levels controls for maintaining specifies performance parameters, diagnostic software for monitoring and estimating the state of the system, and contingent execution software for directing the system through a daily drilling plan while reacting to and recovering from off-nominal situations [3][4]. This drilling strategy assumes that humans remain on Earth, or at least that they do not intervene in drilling operations in real time, wherever they are. Creating an entirely autonomous drilling system that would be deployed on Mars (presumably on its own) and would operate there autonomously until drilling objectives are met, represents a major technological challenge, one that would be potentially very costly to meet.

The Next Generation of NASA Drills

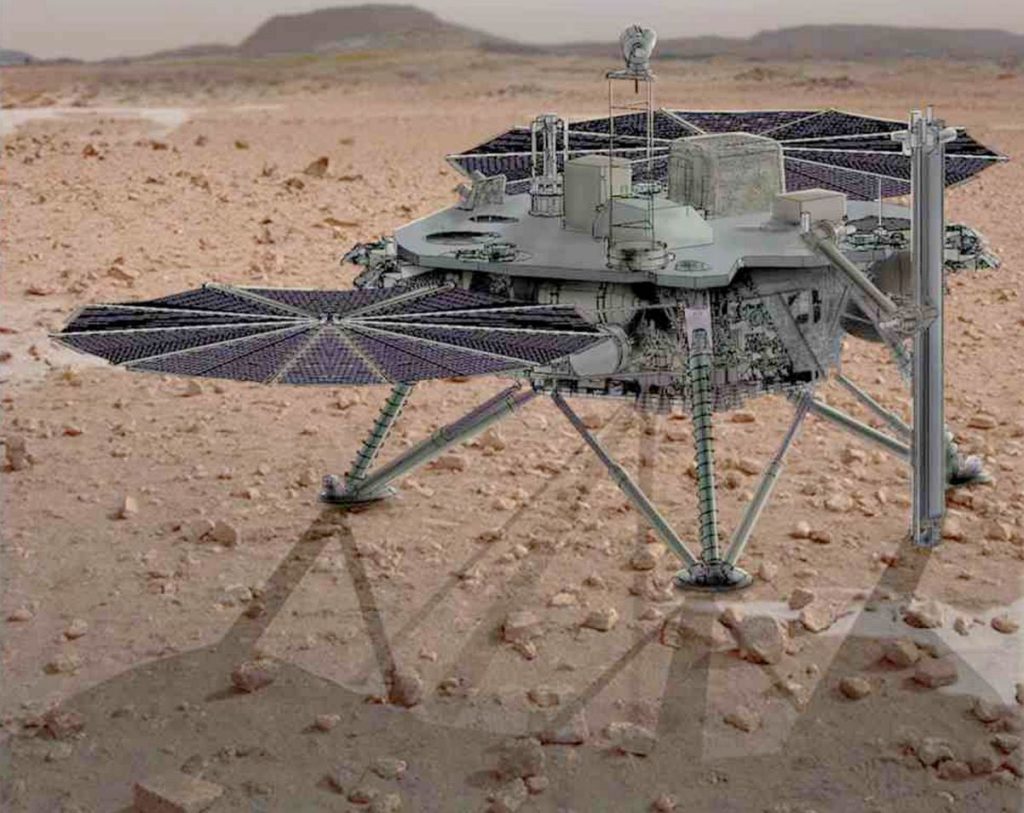

The autonomous Icebreaker drill is a state of the art drilling system developed by Honeybee Robotics and NASA Ames Research Center. Before the drilling initiates, the drill is deployed from a locked horizontal position. Once deployed, it have the following modes for operation [6].

The first stage lead preloads the drill structure against the surface, which is relatively easy. However, the actual drill process requires robust software and low risk drilling protocols, autonomous drilling algorithms and protocols to make drilling operation decision in real-time.

The consequence for not responding to anomaly activities can damage the system, or get permanently stuck in the borehole resulting in ending the mission. Any anomaly could require the drill to pull out and remain on “home” position for further command from Earth. This reduces the risk. The software is dealing with mission-critical and mission-noncritical events. Critical events can lead to a premature end of the mission, such as borehole collapse or if the drill freezes in the borehole.

Conclusion

Remote autonomous operations rely deeply on the combination of Machine Learning algorithms to analyse sensory data. However, huge amount (Big Data) of training data from operations on Earth are used to create a fully autonomous and reliable drilling algorithm to predict what is happening in real-time in the borehole, when human interactions are not permitted due to long distances (In aphelion, Mars can be up to 1000x time distance from Earth to the Moon – 400.000.000 km), which take a radio signal at almost the speed of light, approximately 22 minutes before a sent signal will receive a signal from Mars, a lot undesirable events can happen in that time interval…

References

[1] Briggs, G., & Gross, A. (2002). Technical Challenges of Drilling on Mars: Center for Mars Exploration.

[2] https://openclipart.org/image/2400px/svg_to_png/121795/Mars-Valles-Marineris-by-Merlin2525.png

[3] Glass, B., Cannon, H., Hanagud, S., & Frank, J. (2005). Drilling Automation for Subsurface Planetary Exploration .

[4] Glass, B. J., McKay, C., Thompson, S., & Zacny, K. (2011). Automated Mars Drilling for “Icebreaker”.

[5] http://www.link2universe.net/2013-05-17/mars-icebreaker-life-proposta-per-una-missione-che-trivelli-nel-ghiaccio-marziano/

[6] Zacny, K. (2013). Honeybee Robotics. from http://www.honeybeerobotics.com/